Facilities

Our production facilities have been setup according to international IPC standards. Fully automated high-end latest generation SMT equipment for PCBA production.

Facilities

Facility Access Control

Fingerprint Access Control

All facility area’s are protected with in/out fingerprint readers to open doors and grant access to authorized personnel.

ESD Access Control

Manufacturing area’s have additional ESD access control to ensure our staff is handling your PCBA’s and components in an ESD safe environment.

Facilities

ESD Assurance

ESD Alarm Systems

Throughout our facility we implemented multiple fail-over protected ESD alarm systems that will have visual and audible alarms to notify our staff.

ESD Product Handling

PCBA’s are kept in ESD safe boxes moving from process to process until they are safely packed for shipment.

Facilities

PCBA Handling and Conveyers

Our facility implemented a “No touch” production process.

From Start to Finish the PCBA moves down the line over conveyers.

Facilities

SMT Line Equipment

Latest Generation high-speed SMT lines (2 lines):

Line A : 2015 September

Line B : 2016 March

- Silkscreen Printer

- In-line Solder Paste Inspection

- High Speed IC Mounter

- General Purpose Mounter

- Reflow (N2)

- In-line AOI

Facilities

Reflow Quality Assurance

Our Nitrogen (N2) Reflow Ovens are continuously monitored, calibrated and optimized for every PCBA we produce.

- Reflow Monitoring Solution

- KIC Thermal Test Equipment

Facilities

Machine and AOI Inspection

EVERY unit standard goes through our in-line AOI to confirm every unit produced comes with our commitment to quality.

Facilities

PCBA Panel Separation

V-CUT process for every PCBA after SMT Process is complete. No manual breaking.

No stress or friction on the PCBA and soldered components.

Facilities

Production Side Equipment

Oven

Components are baked prior production (if required).

Off-line SPI

Off-line Solder Paste Inspection (for sample runs and calibration).

Stencil Storage Area

Solder stencils are stored in designated racks to avoid damage between production runs.

Stencil PCB Cleaner

Solder stencils are automatically cleaned prior and after usage.

Feeder Storage/Feeder Carts

Feeders and feeder carts are stored safely between production batches.

Facilities

DIP Line Equipment

DIP line with wave-solder equipment and touch-up / flux removing workbench area.

Facilities

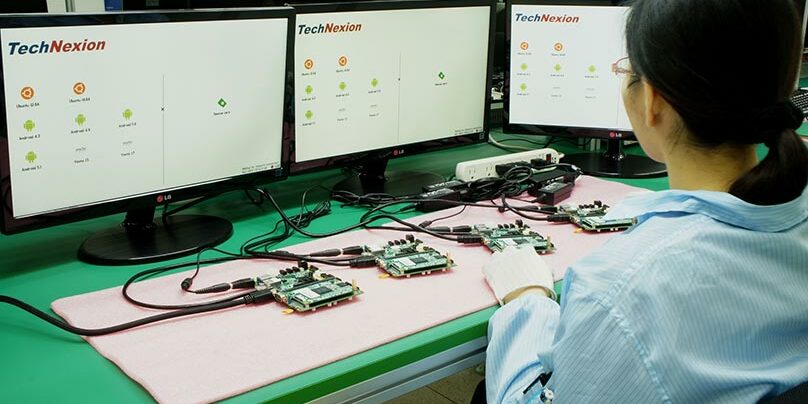

Functional Testing, System Assembly, Packing

Functional Testing for every product 100%.

System Assembling and Packing as per customer request.

Facilities

Analyzing Equipment

BGA Rework Station

VECTech BGA Rework Station with Heating plate.

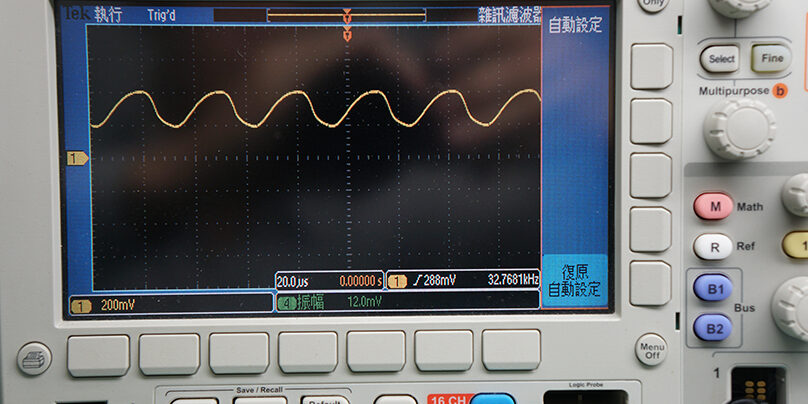

Oscillators and Spectrum Analyzers

TEK Oscilators and Spectrum Analyzers.

Facilities

Measurement Tools

Multimeters

Multimeters and solder stations for selective soldering and analyzing.

Laboratory Power Supplies

Power equipment for performance testing.

Facilities

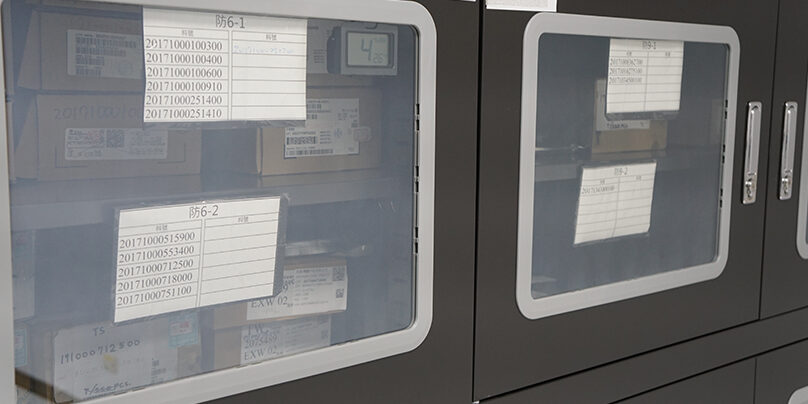

Warehouse Facility

- Humidity and climate controlled dry cabinets for high value and BGA components.

- Components are all stored in their own ESD-safe bins.

- Pharmacy style component dispatch.

Facilities

Warehouse Equipment

Precision Scale

Components are weighed (where possible).

Reel Auto-counter

Reels are counted during: Incoming quality control, dispatch to production line and return for restore after production run.

Facilities

Quality and Traceability Commitment

We guaranty our quality commitment.

Every day.

Every Batch.

Every Unit.

Every Step.

Every Component.

ALWAYS.

Success Stories

Sorry, we couldn't find any posts. Please try a different search.